Advance the technical and economic potential of a circular economy for batteries.

Who

CircuBAT connects the major stakeholders along the complete lifecycle of lithium-ion batteries. Among the are partners from Industry, Governement and NGOs along the complete value chain of a lithium-ion battery lifecycle.

Why

Extending the usable lifetime in first-use applications and increasing the amount of second-use and second-life opportunities allows to minimize the total CO2-footprint of lithium-ion battery systems during the lifetime.

How

Maximizing metal recovery and resource efficiency will provide materials for use in a future manufacturing process and avoid that the battery enters a landfill or other disposal facility with no recovery of any of its remaining value.

What for

A strong framework work package observing, analyzing, and communicating the impacts and opportunities across the life cycle will allow for a holistic view of the whole system and strong collaboration of all partners.

Overview of the subprojects

Step by step to the circular economy

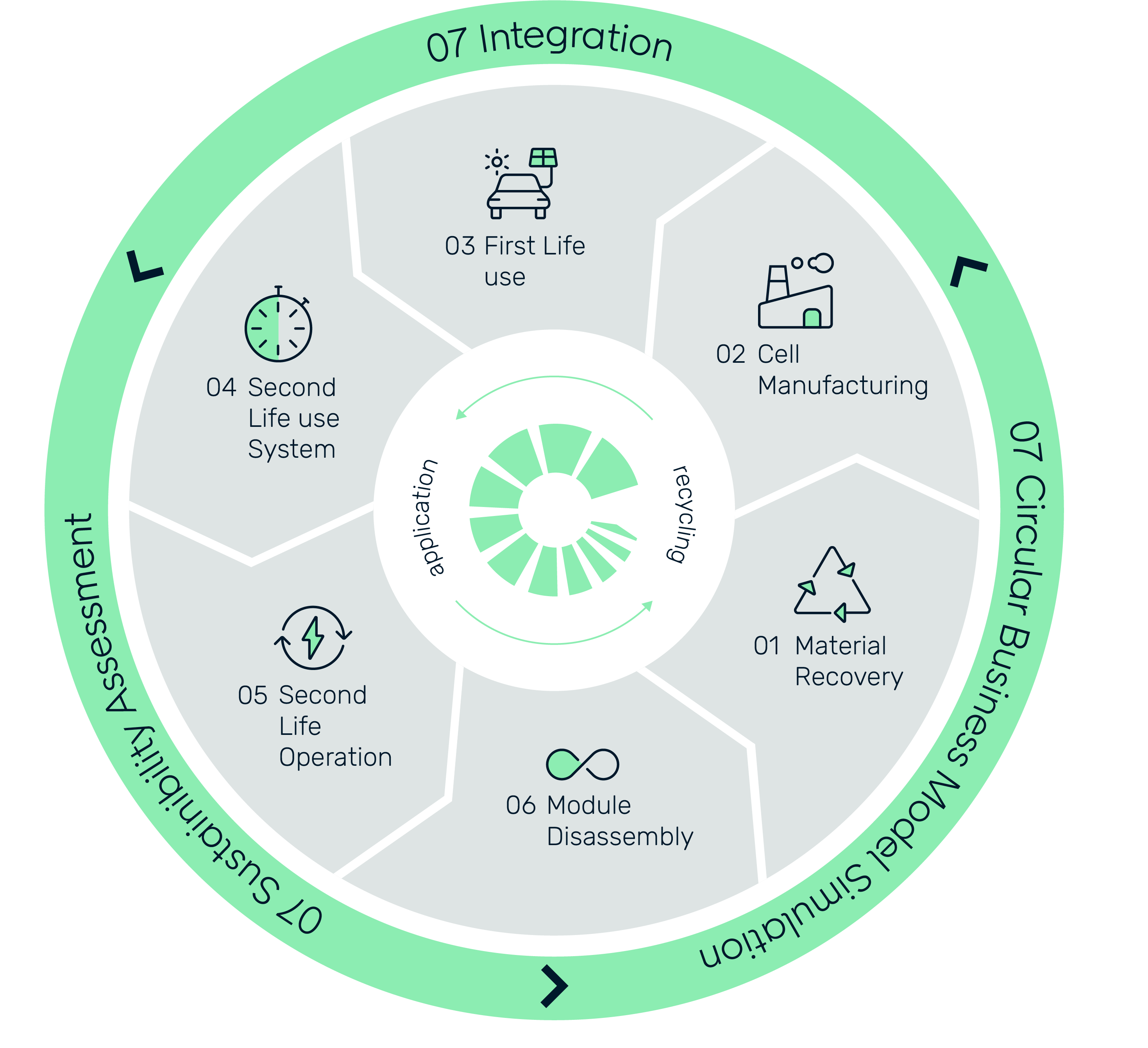

A total of six technical subprojects are organized with strong linkage between them. CircuBAT additionally includes an all encompassing sustainable economic subproject, which interacts strongly with all the other subprojects.

Descriptions

Subprojects explained

Subproject 01: Material Recovery

Subproject 02: Cell Manufacturing

Subproject 03: First Life Use

Subproject 04: Second Life Use System

Subproject 05: Second Life Operation

Subproject 06: Disassembly and Recovery

Subproject 07: Sustainable Business Model

Research Partners

Bern University of Applied Sciences BFH is the Leading House in the CircuBAT project. An additional six Swiss research institutions are involved: Empa, CSEM, the University of St. Gallen (HSG), the Eastern Switzerland University of Applied Sciences (OST), the Switzerland Innovation Park Biel/Bienne (SIPBB) and the EPFL. Together, they coverall relevant academic and research institution levels in Switzerland.